Production of Herbal Protein Isolates with the Enzymatic Hydrolysis Technology

Kudryashov Leonid 1, Diachkova Anna 2, 3*, Tikhonov Sergey 2, Tikhonova Natalya 2 Popova Dina 4, Mozzherina Irina 5, Erdakova Victoria 6

1 V.M. Gorbatov Federal Research Center for Food Systems of Russian Academy of Sciences, St. Talalikhina 26, Moscow, Russia, 109316.

2 Ural State University of Economics, st. 8 Marta /Narodnoy voli, 62/45, Ekaterinburg, Russia, 620144;

3 Ural Federal University named after the first president of Russia B.N. Eltsin, st. Mira 19, Ekaterinburg, Russia, 620002.

4 Kemerovo state University, Krasnoarmeyskaya str., 52, Kemerovo, Russia, 650010.

5 Tyumen Industrial University, st. Volodarsky, 38, Tyumen, Russia, 625000.

6 Sochi State University, st. Plastunskaya, 94, Sochi, Russia, 354000.

*Email: avdb @ yandex.ru

ABSTRACT

The article aims to develop the technology of the production of herbal protein isolates with 41% protein concentration by enzymatic hydrolysis. The technology includes preparing a hydro module from shredded lupine seeds and water in proportion 1:10, hydrolysis of starch with alpha-amylase and glucoamylase, centrifugation, autoclaving of the obtained centrifugate at the temperature of 120-130º С and the pressure of 6х105 Pa for 5-6 hours, cooling it to the temperature of 36º С and hydrolyzing it with trypsin solution in phosphate buffer solution at pH 7.5 for 50-60 minutes, centrifugation, heating and drying at the temperature of 95-100 ºС to get the dry residue concentration of 45% in the protein preparation. Before adding trypsin, it is intensified by blue spectrum light with the luminous flux of 35 µW/cm2. Based on the research, there are regulated quality indicators of protein preparation, storage requirements, and retention periods: retention period of 9 months at the temperature of 0-4 °С with relative humidity not more than 75%.

Key words: Herbal Protein Isolates, Enzymatic Hydrolysis, Lupine, Trypsin, Retention Period.

INTRODUCTION

Nowadays in food engineering, there are various methods of obtaining protein isolates with the use of hydrolysis. For example, the impact of chemical factors – lye and acid. The physical impact such as pressure and temperature are also used. The method of enzymatic splitting has also gained currency. Acid hydrolysis is generally conducted at high temperatures up to 120 ºС with the use of hydrochloric acid for 10-24 hours. The disadvantage of acid hydrolysis is the partial or complete destruction of some amino acids: serine, threonine, tryptophan, proline, and others [1].

Uneven disintegration of amino acids in acid hydrolysis is connected with the different disintegration speed of peptide bonds. Serine, threonine, and methionine have the highest disintegration speed, while valine, leucine, and alanine have the lowest. Due to this, it is recommended to conduct fractional hydrolysis after defined periods (24, 48, and 72 hours). During protein hydrolysis, the effect of acids may be combined with physical factors (pressure). It permits obtaining preparations with various levels of breakdown [2].

Another disadvantage of acid hydrolysis of proteins is that low-molecular-weight peptides receive end structure changes. These peptides may not be identified by body cells. Apart from that, the downside of acid hydrolysis is an aggressive environment and quick depreciation of equipment [3].

To get protein hydrolysate from squid gonad, they usually hydrolyze it with the hydrochloric acid in a quantity of 6-9% of the raw material mass at the temperature from 102 to 105 ºС for 14-18 hours. Afterward, the acid is neutralized with a solution of sodium hydroxide, dried to get the dry residue concentration of 30% and filtrated [4].

Gmyrya designed the method of protein preparation production with the use of processing waste of farm animals and fish. The technology includes acid hydrolysis with the duration of 6-7 hours and neutralizing the acid with lye in electrolyzer [5].

Acid hydrolysis of protein excludes the possibility of microbial pollution of protein hydrolysate because of acid’s bactericide effect. That is why these hydrolysates can be used in medical practice.

Protein preparations can be obtained by lye hydrolysis. The hydrolysates are colorless because there are no melanoidins formed in the process. Protein hydrolysis is generally conducted for collagen [6] and keratinous [7] materials.

It should be noted, that the most perspective way of producing protein hydrolysates is the enzymatic method. Hydrolysis of herbal and animal proteins is processed with proteolytic enzymes at the temperature of 35-50 ºС and defined pH. The advantage of enzymatic hydrolysis is the high preservation of amino acids [8].

Enzymes are usually classified by their specificity and the kind of active center, which consists of the catalytic, binding, and regulatory site [9]. This technology uses enzymes produced by the human gastric mucosa, intestinal mucosa, and animal pancreas, in particular, trypsin, chymotrypsin, chymosin, elastase, and collagenase [10].

There is a lot of raw material for a protein supplement [11-13]. Chan and coauthors use rice for substitution of egg protein [14]. Among other herbal enzymes papain, bromelain, ficin, and asclepain are often used for protein hydrolysis. The advantage of herbal enzymes is in their low specificity and high activity even at 0 ºС [15]. There are proteolytic enzymes of hydrobionts, which have the most activity at pH 5-8 and the temperature of 37 ºС [16], fungal, actinomycin, bacterial, and bacilli enzymes. Protease obtained from microorganisms in many cases can also split collagen, elastin, and keratin [17]. Protein hydrolysis can be conducted not only with pure enzymes but also with pancreas mince, cattle abomasum, dry enzymatic preparations based on them [18, 19], and enzymes synthesized by microorganisms, for example, neutral protease is derived from A. oryzae, В. amyloliquefaciens, Rhizopussp, lye protease -from В. licheniformis, В. Thennoproteolyticus, renin – from Endothia parasitica, Mucor miehei, Mucor pussilu.

To prepare fermented protein hydrolysate from casein [20], there is a method: 1 kg of casein is sedimented with sulfuric acid and diluted with water at 1:10 proportion, pH is brought to 8.0 with lye and heated to 37 ºС, and subsequently, there are 100 ml of 1% solution of proteolytic enzyme added. Afterward, the product is hydrolyzed for 6 hours, and the enzyme is inactivated.

A protein hydrolyzate is obtained from plant materials (flaxseed flakes) according to the technology: 20 kg of flaxseed flakes is added to an aqueous yeast hydrolyzate (4 kg of yeast per 1 m3), stirred and left for 6 hours, then enzymes are added and fermented for 30 minutes at a temperature of 40 °С, afterward, the enzymes are inactivated by temperature [21].

In industrial production, hydrolysates with a level of hydrolysis of 55-65% (relative content of amine nitrogen of the total) and a degree of proteolysis of 90-94% (relative content of residual nitrogen of the total) are considered deep enough.

Due to this, the research aims to develop the technology of the production of herbal protein isolates obtained by enzymatic hydrolysis.

MATERIALS AND METHODS

Research objects: lupine seeds (narrow-leaved variety 53, rainbow variety), enzymes.

Studies of the quality of the protein preparation were conducted according to generally accepted methods.

The protein preparation was obtained from lupine seeds. The rationale for using lupine seeds as a raw material for obtaining a protein preparation is a high protein content (30-50%), the lupine protein of all plant proteins is most balanced in terms of the amino acid index. It contains glutamic acid up to 26%, aspartic acid up to 13%, arginine up to 13%, leucine up to 10% [22, 23]. Villa and coauthors add that the thermal treatment of lupin seeds can decrease allergic components [24].

At the same time, the quality of legume protein, including lupine, is determined not only by its amino acid composition but also by the number of trypsin inhibitors. Lupine seeds are defined by a low content of proteolytic enzyme inhibitors – 2.5 g/kg, when compared with soy, in which the content reaches 29 g/kg.

The results were processed by the method of variation statistics using the Microsoft Excel XP, Statistica 8.0, confidence level was 0.95, and 0.999. The research results are analyzed with the method of analysis of variance with the use of the Student coefficient.

RESULTS AND DISCUSSION

The present research includes the developed technology of the protein supplement. It consists of the next steps. Lupine seeds (narrow-leaved variety 53, rainbow variety) are crushed in a laboratory mill and filled with distilled water in a proportion of 1:10. Hydrolysis of starch is carried out by introducing the enzyme alpha-amylase (amylosubtilin) and glucoamylase (glucavamarine) at a temperature of 37 ℃. After 3 hours, the solution is centrifuged. The resulting centrifuge is placed in an autoclave and heated to a temperature of 120-130 ° C at a pressure of 6x105 Pa for 5-6 hours. These technological conditions allow destroying trypsin inhibitors. The resulting mass is cooled to a temperature of 36 ° C, pour 0.5% trypsin solution on a phosphate buffer solution with a pH of 7.5, incubated for 50-60 minutes, then centrifuged and the enzyme is inactivated for 3-4 hours at a temperature of 95-100 ºC to get the dry residue in protein concentrate of 45%.

Before the introduction of trypsin into the solution, it was activated with blue spectrum light with a luminous flux of 35 μW/cm2 using an Avers-san bio lamp (manufactured by NPK Avers, Moscow) for 50-60 minutes. The enzyme activity was determined by the breakdown of gelatin.

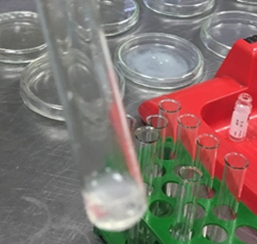

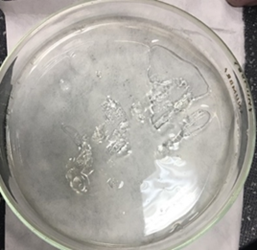

Dilutions of 1:2, 1:8, 1:16, 1:32, 1:64, 1:128, 1:256 of a 0.5% trypsin solution in phosphate buffer solution (pH 7.5) were used to estimate trypsin activity. Trypsin activity was expressed in units of dilution at which the breakdown of gelatin begins. It was found that the enzyme-treated with light is active at a dilution of 1:128 (pictures 1,2).

Picture 1: Trypsin solution (0.5%) in phosphate buffered solution (pH 7.5)

Picture 2: Determination of trypsin activity by the breakdown of gelatin (dilution 1:128)

In the result of the analysis, it was found that the enzyme was 128 units. At the same time, the activity of untreated trypsin was 16 units. The research has shown that the amount of protein in the protein preparation was 41.6%, water – 56.2%.

Table 1 presents the microbiological parameters of a protein preparation obtained from lupine seeds in vacuum packaging.

Table 1: Microbiological parameters of a protein preparation obtained from lupine seeds

|

Parameter |

|||||

|

The mass of the product (g) in which pathogenic microorganisms, including Salmonella, are not allowed |

Number of mesophilic aerobic and facultative anaerobic microorganisms, CFU/g (not more than) |

The mass of the product (g) in which bacterium of intestinal (coliforms) are not allowed

|

The mass of the product (g) in which sulfite-reducing clostridia are not allowed |

Yeast, CFU/g (not more than) |

Mold, CFU/g (not more than) |

|

Permissible level according to TR TS 021/2011 "On food safety" |

|||||

|

25 |

5х103 |

0,1 |

0,1 |

100 |

100 |

|

0 days of storage |

|||||

|

Not distinguished |

1х10 |

Not distinguished |

Not distinguished |

Not distinguished |

Not distinguished |

|

Not distinguished |

1х10 |

Not distinguished |

Not distinguished |

Not distinguished |

Not distinguished |

|

After 30 days of storage |

|||||

|

Not distinguished |

6х10 |

Not distinguished |

Not distinguished |

Not distinguished |

Not distinguished |

|

After 180 days of storage |

|||||

|

Not distinguished |

3х102 |

Not distinguished |

Not distinguished |

Not distinguished |

Not distinguished |

|

After 360 days of storage |

|||||

|

Not distinguished |

7х102 |

Not distinguished |

Not distinguished |

Not distinguished |

Not distinguished |

As a result of the present research of the microbiological parameters of the protein preparation, it was found that after 360 days of storage all the tested samples comply with the requirements of food safety.

Based on the studies, regulated quality indicators, as well as the timing and storage conditions of the protein preparation from lupine seeds, were established (Table 2).

Table 2 presents the regulated quality indicators of a protein preparation from lupine seeds.

Table 2: Regulated quality indicators of the protein preparation from lupine seeds

|

Parameter |

Property |

|

Color |

Light yellow to light brown |

|

Taste |

Herbal |

|

Consistency |

Solid |

|

Protein (g/100g, not more than) |

35 |

Thus, as a result of the present research, it was established that the optimal shelf life is 9 months at a temperature of 0 to 4°C with a relative humidity of not more than 75%.

CONCLUSION

Therefore, based on the research, the technology of the protein isolate from lupine seeds by enzymatic hydrolysis was developed. Studies of organoleptic characteristics, protein, and moisture content were conducted. Regulated indicators, shelf life, and storage conditions were established: 9 months at a temperature of 0 to 4°C with a relative humidity of not more than 75%. The results can be implemented in the food industry.

ACKNOWLEDGMENTS

This research received no external funding. The authors declare no conflict of interest (Kudryashov L., Diachkova A., Tikhonov S., Tikhonova N., Tretyakova I, Popova D., Mozzherina I., and Erdakova V.).

REFERENCES

- Méndez, Lai С. Y. Regeneration of amino acids from thiazolines formed in the Edman degradation, Anal. Biochem., 1975, v. 68 : 47-5.

- Frokjaer, S. Use of Hydrolysates for Protein Supplementation, Food technology, 1994, 10: 86-88.

- Rassulin, Yu., A., Mardanyan, М.М., Sokovykh V.S., Neklyudov, A.D. Study of possible ways to improve industrial hydrolysates, Pharmaceutical Chemistry Journal, 1983, 7 : 850-855.

- Besedina TV, SA, Korolev AN, Konoplyanikov AG, Novikova MV, Rekhina N.I., Chimirov Yu.I. A Product from protein-carbohydrate-containing raw materials of water origin and the method for its preparation, Patent 2093040 RF, authors application 3000456/14 of September 7, 1997, 2.

- Gmyrya I.F. A method of obtaining a protein hydrolysate, patent 2195130 RF, Application 2001113003/13, 2001, 4.

- A method of obtaining slightly colored collagen hydrolysates, patent 226153 GDR, Patent Invention countries of the world, 1986, vol. 57, part 1.

- Goryaev, M.I., Bykova, L.N., Kodovbetskaya, V.N., Bobrovskaya, T.G., Izatulaev, E.A. The biological value of peptone obtained from keratin-containing raw materials, Applied biochemistry and microbiology, 1981, 17, 2 : 273-27

- Maksimyuk, N.N. Maryanovskaya, Yu.V. On the advantages of the enzymatic method of producing protein hydrolysates, Fundamental research, 2009, 1: 34-35.

- Klesov A.A. Enzymatic Catalysis, ed. Moscow State University, 1984 : 216.

- Albenzio, M., Santillo, A., Caroprese, M., Malva, A. D. and Marino, R. Bioactive Peptides in Animal Food Products, Foods, 2017, 6(5), 35.

- Nagdalian A A, Oboturova N P, Povetkin S N, Ahmadov V T, Karatunov V A, Gubachikov A Z, Kodzokova M A, Orazaeva L N, Orazaev A N. Insect’s Biomass as a Livestock Feed. Study of the Impact of Insectoprotein on the Livestock Vitals. Pharmacophores. 2020; 11(1): 27-34.

- Saraswat N, Wal P, Pal R S, Wal A, Pal Y, Maurya D. Current review on IRS-1, JNK, NF-ΚB & m-TOR pathways in Insulin Resistance. Pharmacophores. 2020; 11(1): 1-14.

- Hasimun P, Aligita W, Nopitasari I. Anti Anemic and Analgesic Activity of Sauropus Androgynous L Merr on Female Mice Model. Int. J. Pharm. Phytopharm. Res. 2018; 8(1): 98-102.

- Chan, Y.-J., Lu, W.-Ch., Lin, H.-Y., Wu, Z.-R., Liou, Ch.-W. and Li, P.-Hs. Effect of Rice Protein Hydrolysates as an Egg Replacement on the Physicochemical Properties of Flaky Egg Rolls, Foods, 2020, 9(2), 245.

- El-Gharbawi, M. Whitaker, LR., J, Food Sd, 1963, 8 : 128.

- Nozdrina, T.D. Modification of low-grade meat raw materials by proteolytic hydrobiotic enzymes. Thesis of Dissertation, M., 1996 : 20.

- Bendas L.G. Fodder yeast as a source of nutrient media for the cultivation of microbes, Laboratory, 1971, 1 : 43-45.

- Zhuravskaya H.K. Prospects for the use of an enzyme preparation obtained from the entrails of aquatic organisms to increase the quality indicators of meat products, Materials of the International scientific and technical conference "Applied biotechnology on the threshold of the XXI century" M., 1995 : 54.

- Leni, G., Soetemans, L., Caligiani, A., Sforza, S. and Bastiaens, L. Degree of Hydrolysis Affects the Techno-Functional Properties of Lesser Mealworm Protein Hydrolysates, Foods, 2020, 9(4), 381.

- Artyukov, A.A ., Kozlovskaya, E.P., Kozlovsky, A.S., Kofanova, N.N., Alshevskaya, E.K., Sakharov, I.Y., Vozhzhova, E.I. Method for producing protein hydrolysate, patent 2039460 RF, Application: 93031307/13, 1995.

- Kaldin, R.Yu., Golubev, A.I. The method of obtaining fodder protein hydrolysate, patent 2372787C1 RF, 2009.

- Domoroschenkova, M.L., Eggie, E.E., Mehdiyev, V.S., Demyanenko, T.F. Narrow-leaved lupine – a promising source of dietary protein, Storage and processing of agricultural raw materials, 2009, 10 : 53-56.

- Krasilnikov, V.N., Mehdiyev, V.S., Domoroschenkova, M.L., Demyanenko, T.F., Gavrilyuk, I.P., Kuznetsova L.I. Prospects for the use of proteins from lupine seeds of narrow-leaved domestic selection in gluten-free flour confectionery, Food industry, 2010, 2 : 40-43.

- Villa, C., Mónica Moura, M. B. M. V., Costa, J. and Mafra I. Immunoreactivity of Lupine and Soybean Allergens in Foods as Affected by Thermal Processing, Foods, 2020, 9(3), 254.